Where one or a number of very simple items need to be made it is sometime easy to make a wooden plug in the right shape and then press this plug into a sheet of heated plastic allowing the plastic to conform to the shape of the plug before it cools. I have found this process useful for making things like the hulls for ships boats. This process does not produce a detailed replica of the plug but it gives you a good shell on which to add detail as required. I have found the process a bit inconsistent but if you are prepared to persevere then you can achieve acceptable results.

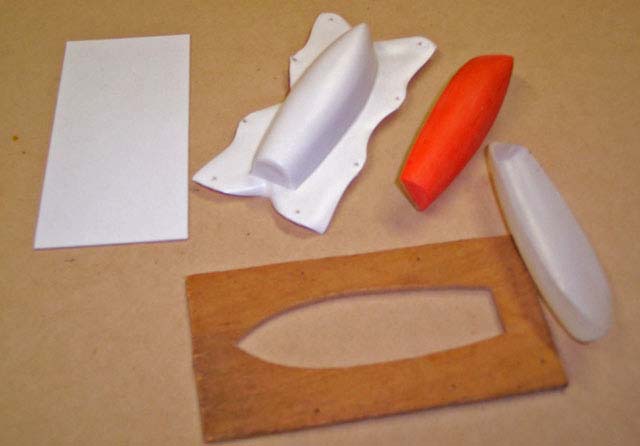

The pictures below show this simple process.

The plastic sheet has been fixed to the plywood with drawing pins and placed between two larger pieces of wood. The plastic was slowly heated with the hot air gun until it started to sag in the middle. The wooden hull former was then quickly pushed into the plastic ensuring that it went far enough through to allow for trimming to the correct size. The plastic cools very quickly and the former can then be removed.

The plastic sheet has been fixed to the plywood with drawing pins and placed between two larger pieces of wood. The plastic was slowly heated with the hot air gun until it started to sag in the middle. The wooden hull former was then quickly pushed into the plastic ensuring that it went far enough through to allow for trimming to the correct size. The plastic cools very quickly and the former can then be removed.